Your location: News >>

2026/1/30The natural gas peak shaving and supply guarantee capacity of the Tarim Oilfield has been continuously rising.On January 26, it was learned that the Tarim gas storage cluster, including the Yahe and Kokya gas storage facilities, has seen a continuous increase in gas production since the start of the winter gas extraction this year, effectively supporting the winter gas supply demand. During this winter supply period, Tarim Oilfield has actively played the role of underground gas storage

2026/1/30The natural gas peak shaving and supply guarantee capacity of the Tarim Oilfield has been continuously rising.On January 26, it was learned that the Tarim gas storage cluster, including the Yahe and Kokya gas storage facilities, has seen a continuous increase in gas production since the start of the winter gas extraction this year, effectively supporting the winter gas supply demand. During this winter supply period, Tarim Oilfield has actively played the role of underground gas storage

View More 2026/1/23The first trial of the electric pump fishing-uplift technology in the Tarim Oilfield was a success.On January 21st, the Wunan 3-2-13X well of the Tarim Oilfield was officially put into operation. This well successfully completed the lowering of the retrievable electric pump and achieved a qualified trial pumping within the middle of this month. It realized the application of the retrievable electric pump lifting technology at a depth of 2500 meters, providing a new technical ap

2026/1/23The first trial of the electric pump fishing-uplift technology in the Tarim Oilfield was a success.On January 21st, the Wunan 3-2-13X well of the Tarim Oilfield was officially put into operation. This well successfully completed the lowering of the retrievable electric pump and achieved a qualified trial pumping within the middle of this month. It realized the application of the retrievable electric pump lifting technology at a depth of 2500 meters, providing a new technical ap

View More 2026/1/9The intensive overall fracturing technology of Jilin Oilfield has enabled the old oilfield to achieve new energy production.On January 5th, a reporter learned from the Oil and Gas Technology Research Institute of Jilin Oilfield that the Jilin Oilfield's intensive overall fracturing technology has focused on the capacity building of conventional oil, precisely exerting its technical support role, and achieving a new breakthrough in the capacity building of old oilfields. Up to now, the Jilin Oilfield ha

2026/1/9The intensive overall fracturing technology of Jilin Oilfield has enabled the old oilfield to achieve new energy production.On January 5th, a reporter learned from the Oil and Gas Technology Research Institute of Jilin Oilfield that the Jilin Oilfield's intensive overall fracturing technology has focused on the capacity building of conventional oil, precisely exerting its technical support role, and achieving a new breakthrough in the capacity building of old oilfields. Up to now, the Jilin Oilfield ha

View More 2026/1/2The high-temperature heat pump system of Jilin Petrochemical Company has achieved remarkable energy-saving effects.On December 22, the author learned that the high-temperature heat pump system of the third thermal station, a key supporting project for the western transformation and upgrading of Jilin Petrochemical, was successfully put into operation. It supplies qualified heating and hot water for the 600,000-ton/year styrene and other facilities and factory buildings, marking a revolutionary

2026/1/2The high-temperature heat pump system of Jilin Petrochemical Company has achieved remarkable energy-saving effects.On December 22, the author learned that the high-temperature heat pump system of the third thermal station, a key supporting project for the western transformation and upgrading of Jilin Petrochemical, was successfully put into operation. It supplies qualified heating and hot water for the 600,000-ton/year styrene and other facilities and factory buildings, marking a revolutionary

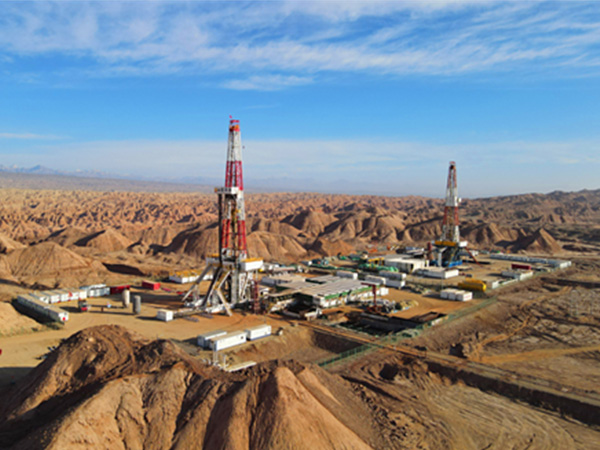

View More 2025/12/25The Tarim Oilfield has put more than 100 new wells into production this year.As of December 21, the Tarim Oilfield has put 113 new wells into production this year, with a new crude oil production capacity of 1.0923 million tons and a natural gas production capacity of 2.234 billion cubic meters. Behind this achievement lies the combined efforts of the oilfield's "map-based operation" deadline mechanism, full-chain technical support, and refined management.

2025/12/25The Tarim Oilfield has put more than 100 new wells into production this year.As of December 21, the Tarim Oilfield has put 113 new wells into production this year, with a new crude oil production capacity of 1.0923 million tons and a natural gas production capacity of 2.234 billion cubic meters. Behind this achievement lies the combined efforts of the oilfield's "map-based operation" deadline mechanism, full-chain technical support, and refined management.

View More 2025/12/12The Daqing Oilfield has maintained a stable output of over 10 million tons for 24 consecutive years through tertiary oil recovery.As of December 3rd, Daqing Oilfield, the world's largest research and production base for tertiary oil recovery, has achieved a tertiary oil recovery output of over 10 million tons in 2025, maintaining an output of over 10 million tons for 24 consecutive years, with a cumulative output of 330 million tons, reaching a new peak in production. Tertiary oil recovery involves injecting

2025/12/12The Daqing Oilfield has maintained a stable output of over 10 million tons for 24 consecutive years through tertiary oil recovery.As of December 3rd, Daqing Oilfield, the world's largest research and production base for tertiary oil recovery, has achieved a tertiary oil recovery output of over 10 million tons in 2025, maintaining an output of over 10 million tons for 24 consecutive years, with a cumulative output of 330 million tons, reaching a new peak in production. Tertiary oil recovery involves injecting

View More 2025/11/28The self-developed integrated production line of Huabei Oilfield has enhanced the efficiency of pipeline business.On November 24th, the "laser rust removal + automatic anti-corrosion" integrated pipeline production line independently developed by Tiancheng Lide Company of Huabei Oilfield was successfully put into operation and has been running stably. This production line adopts a seamless design of "rust removal - anti-corrosion", and through process integration and intelligent upgrading, it

2025/11/28The self-developed integrated production line of Huabei Oilfield has enhanced the efficiency of pipeline business.On November 24th, the "laser rust removal + automatic anti-corrosion" integrated pipeline production line independently developed by Tiancheng Lide Company of Huabei Oilfield was successfully put into operation and has been running stably. This production line adopts a seamless design of "rust removal - anti-corrosion", and through process integration and intelligent upgrading, it

View More 2025/11/21Changqing Oilfield Pioneers a New Path for Shale Oil Production GrowthOn November 12th, it was learned that a well at the shale oil fracturing site in the main oilfield area of Longdong in Changqing Oilfield successfully completed the carbon dioxide energy-enhanced fracturing operation and simultaneously achieved multiple integrated tests including casing external optical fiber monitoring, wellbore digital data collection, and dual-well microseismic

2025/11/21Changqing Oilfield Pioneers a New Path for Shale Oil Production GrowthOn November 12th, it was learned that a well at the shale oil fracturing site in the main oilfield area of Longdong in Changqing Oilfield successfully completed the carbon dioxide energy-enhanced fracturing operation and simultaneously achieved multiple integrated tests including casing external optical fiber monitoring, wellbore digital data collection, and dual-well microseismic

View More 2025/11/14Liaoyang Petrochemical: Adapting to the Seasons to Ensure the Production of Low Pour Point DieselAs temperatures in Northeast China continue to drop, the pressure to ensure a steady supply of low pour point diesel has been increasing. Liaoyang Petrochemical has closely followed market demand changes, adjusted resource allocation, and optimized production plans to significantly increase the output of low pour point diesel. As of now, the daily average output of -35 diesel at L

2025/11/14Liaoyang Petrochemical: Adapting to the Seasons to Ensure the Production of Low Pour Point DieselAs temperatures in Northeast China continue to drop, the pressure to ensure a steady supply of low pour point diesel has been increasing. Liaoyang Petrochemical has closely followed market demand changes, adjusted resource allocation, and optimized production plans to significantly increase the output of low pour point diesel. As of now, the daily average output of -35 diesel at L

View More 2025/11/7The automatic pipe pusher device of the Downhole Operations Company of Dagang Oilfield reduces burden and empowers.On November 3rd, at the well maintenance site of Well West 17-9 in the Downhole Operations Company of Dagang Oilfield, employees completed the operation tasks that previously required the cooperation of two positions by controlling the newly developed automatic pipe pusher device. Traditional minor well maintenance is a labor-intensive industry. On-site employees have been deali

2025/11/7The automatic pipe pusher device of the Downhole Operations Company of Dagang Oilfield reduces burden and empowers.On November 3rd, at the well maintenance site of Well West 17-9 in the Downhole Operations Company of Dagang Oilfield, employees completed the operation tasks that previously required the cooperation of two positions by controlling the newly developed automatic pipe pusher device. Traditional minor well maintenance is a labor-intensive industry. On-site employees have been deali

View More 2025/10/31The Liaohe Oilfield has put a new device into use, reducing the comprehensive cost per ton of liquid by more than 20%.On October 28th, it was learned from Liaohe Oilfield that after the Shu 5 Combined Station of the oilfield adopted the new-generation low-temperature electric dehydration device, the water content of crude oil leaving the station was stably controlled within 0.3%, and the comprehensive cost per ton of liquid decreased by more than 20%. Dehydrating heavy oil has always been a diff

2025/10/31The Liaohe Oilfield has put a new device into use, reducing the comprehensive cost per ton of liquid by more than 20%.On October 28th, it was learned from Liaohe Oilfield that after the Shu 5 Combined Station of the oilfield adopted the new-generation low-temperature electric dehydration device, the water content of crude oil leaving the station was stably controlled within 0.3%, and the comprehensive cost per ton of liquid decreased by more than 20%. Dehydrating heavy oil has always been a diff

View More 2025/10/24Jidong Oilfield Develops a New Type of Filter Core Carbonization Cleaning Device to Reduce Costs and Increase EfficiencyOn October 22nd, at the Laoyema Joint Station of the Oil and Gas Gathering and Transportation Company of Jidong Oilfield, employees used a newly developed carbonization cleaning device for filter cores to clean the filter cores. The cleaning process was both convenient and environmentally friendly. In the oil and gas gathering and transportation production system, the filter core

2025/10/24Jidong Oilfield Develops a New Type of Filter Core Carbonization Cleaning Device to Reduce Costs and Increase EfficiencyOn October 22nd, at the Laoyema Joint Station of the Oil and Gas Gathering and Transportation Company of Jidong Oilfield, employees used a newly developed carbonization cleaning device for filter cores to clean the filter cores. The cleaning process was both convenient and environmentally friendly. In the oil and gas gathering and transportation production system, the filter core

View More 2025/9/26The digital transformation of BaiKouQuan Oil Production Plant in Xinjiang Oilfield has achieved quality and efficiency improvement.As of now, the Internet of Things (IoT) online rate of the BaiKouQuan Oil Production Plant in Xinjiang Oilfield has remained stable at 98%, with data accuracy reaching 99% and equipment integrity rate maintained at 95%. The plant has shifted from merely "building well" to "managing well" and "utilizing well", laying a solid foundation for the digital and intelligent transformation

2025/9/26The digital transformation of BaiKouQuan Oil Production Plant in Xinjiang Oilfield has achieved quality and efficiency improvement.As of now, the Internet of Things (IoT) online rate of the BaiKouQuan Oil Production Plant in Xinjiang Oilfield has remained stable at 98%, with data accuracy reaching 99% and equipment integrity rate maintained at 95%. The plant has shifted from merely "building well" to "managing well" and "utilizing well", laying a solid foundation for the digital and intelligent transformation

View More 2025/9/19The Dagang Oilfield has adopted differentiated water injection to tap the potential of remaining oil.As of September 10th, Dagang Oilfield has carried out differentiated water injection management in 40 key blocks, achieving a reduction in natural decline and an increase in oil production of over 30,000 tons during the stage. The natural decline rate has decreased by 1.7 percentage points compared to the same period last year, with significant results in tapping the remaining oil

2025/9/19The Dagang Oilfield has adopted differentiated water injection to tap the potential of remaining oil.As of September 10th, Dagang Oilfield has carried out differentiated water injection management in 40 key blocks, achieving a reduction in natural decline and an increase in oil production of over 30,000 tons during the stage. The natural decline rate has decreased by 1.7 percentage points compared to the same period last year, with significant results in tapping the remaining oil

View More 2025/9/12Characteristics and Applications of Emergency Shut-off Solenoid ValvesFeatures of the emergency shut-off solenoid valve: Performance features: Butterfly piston, anti-corrosion and wear-resistant, single-ring seal, leakage prevention guide setting, fault elimination, instant power-on, rapid cut-off, self-holding open, manual reset, specially designed coil, ultra-long service life. Applications of the emergency shut-off solenoid valve: 1. Connect with fla

2025/9/12Characteristics and Applications of Emergency Shut-off Solenoid ValvesFeatures of the emergency shut-off solenoid valve: Performance features: Butterfly piston, anti-corrosion and wear-resistant, single-ring seal, leakage prevention guide setting, fault elimination, instant power-on, rapid cut-off, self-holding open, manual reset, specially designed coil, ultra-long service life. Applications of the emergency shut-off solenoid valve: 1. Connect with fla

View More

+86-21-66059111

Company profile

Company profile Chairman's speech

Chairman's speech Company honor

Company honor Corporate culture

Corporate culture Enterprise environment

Enterprise environment Water Conservancy and Water Works

Water Conservancy and Water Works  Building HVAC

Building HVAC Technical team

Technical team Production team

Production team After sales service commitment

After sales service commitment Technical data download

Technical data download ERP order query

ERP order query Company news

Company news Industry dynamic

Industry dynamic Technical knowledge

Technical knowledge Headquarters

Headquarters Domestic sales department

Domestic sales department International business division

International business division

+86-21-66059111

+86-21-66059111